Introduction

Repmold is not a buzzword. It’s a production approach that manufacturers are using because it solves very specific problems. Making molds the traditional way takes too much time and money. On top of that, industries are being pressured to reduce waste. Repmold tries to answer both. It replicates a master mold design quickly, with fewer resources, and it’s already being tested in different sectors.

What Repmold Actually Does

The process is about duplication. Instead of carving molds from scratch with CNC machines or relying on long casting methods, a base model is made and then copied through Repmold techniques. What takes weeks with older methods can often be done in days.

That’s why companies are interested. Faster mold turnaround means faster prototypes and shorter delays. And because there’s less waste material compared to cutting away blocks of steel or plastic, it’s cleaner.

Why Industries Care About It

Manufacturers today are balancing two demands: speed and cleaner processes. Customers don’t wait months for a sample part anymore, and regulators want less energy waste. Repmold fits this demand by cutting cycle times and reusing materials that would otherwise be wasted.

Cost is another factor. By avoiding massive machining setups and reusing feedstock, Repmold lowers production costs. Lower cost, same accuracy, and faster results are what make it appealing to companies that want to stay competitive.

Environmental Side of Repmold

Sustainability is not marketing here. Conventional mold production is resource heavy. Large chunks of raw material are cut away and discarded, often with no reuse. Repmold allows recycled or renewable polymers and resins to be part of the process. Less raw waste ends up in landfills, and less energy is consumed during shaping.

This doesn’t make manufacturing completely green, but it shifts it in the right direction. For businesses trying to meet sustainability reports or certifications, this technology helps.

Comparing Precision and Output

One question always comes up: does speed mean lower accuracy? The answer is mostly no. Repmold molds can reproduce a master with very fine detail, often close to the precision of traditional methods. For prototypes or medium production runs, it’s good enough.

The weak point is durability. Traditional steel molds made through CNC can run for millions of cycles. Repmold molds can’t handle that level of stress yet. That’s why industries use it mainly for short runs, testing phases, or situations where updates to design are frequent.

Where It’s Being Used Right Now

Different industries are already putting Repmold into practice:

- Automotive: trying out new parts before mass production.

- Medical devices: prototypes that need high accuracy delivered quickly.

- Consumer products: short-run items or custom goods.

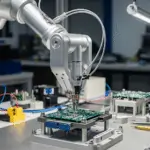

- Electronics: cases, housings, and parts that change often.

The common factor is the need for speed and flexibility rather than huge-volume runs.

3D Printing and Repmold

The combination of 3D printing and Repmold is where things get interesting. A master part can be printed within hours, then replicated through Repmold for testing or short runs. Instead of machining or casting a prototype from scratch, manufacturers can jump from CAD to physical mold within days.

This makes customization easier too. If a client requests changes, the design can be reprinted and remolded quickly without months of rework.

Environmental Benefits Beyond Material Use

The ecological impact is not just about cutting waste. It’s also about cutting energy demand. Traditional machining involves long tool paths, grinding, polishing, and all of that consumes electricity. With Repmold, fewer steps mean less energy is spent.

Multiply that across industries, and the overall effect is smaller carbon emissions. It’s not a full solution, but it’s a practical step forward.

Drawbacks and Limits

It’s not perfect. Repmold is not designed to replace heavy-duty, high-volume mold making. A few limitations stand out:

- Shorter lifespan compared to steel molds.

- Skill needed – technicians must know how to control conditions.

- Material limits – not every polymer or resin works well.

For companies that need millions of identical parts, traditional machining still wins. For small batches or prototypes, Repmold is better suited.

Future Development: AI in Repmold

Looking at where it could go next, artificial intelligence will likely play a role. AI tools can scan molds, predict wear points, and adjust designs automatically. This would reduce trial and error, extend mold lifespan, and cut down on downtime.

AI-assisted Repmold could give factories an even faster path from digital file to finished part. It’s not there yet, but early discussions point in this direction.

Mistakes People Make with Repmold

Some companies jump in expecting it to replace everything. That’s the first mistake. It’s not suited for long production runs. Another issue is using the wrong materials that shorten mold life. And sometimes management underestimates how much operator skill still matters, thinking the process is plug-and-play when it isn’t.

Learning these points early saves time and prevents waste.

If Businesses Don’t Adopt

Choosing not to adapt methods like Repmold may mean higher expenses and slower timelines. Competitors that use it can deliver prototypes and short-run parts faster and with lower costs. That difference can be enough to lose contracts. In a market that values both speed and cleaner practices, ignoring these technologies isn’t smart.

FAQs

1. Can Repmold be used for mass production?

No. It’s mainly for prototypes and short runs.

2. How much faster is Repmold compared to CNC?

It can cut production time from months to days.

3. Does it work with 3D printing?

Yes. Many companies combine both for faster results.

4. Is the detail the same as CNC molds?

Close enough for prototypes and low-volume parts.

5. What are the main benefits?

Lower cost, faster results, reduced waste, and flexibility.

Conclusion

Repmold is a practical manufacturing method that speeds up mold production and cuts down on waste. It doesn’t replace traditional molds for long-term use, but it solves real problems for companies needing prototypes or short batches.

The technology’s environmental advantages and lower costs make it appealing right now. If AI and material improvements continue, it could expand into wider applications.

Author Bio

Jordon writes about manufacturing technology and sustainable production methods. He focuses on explaining processes in clear language for professionals and curious readers who want straight answers rather than jargon.